playlist details

1

ironmannn

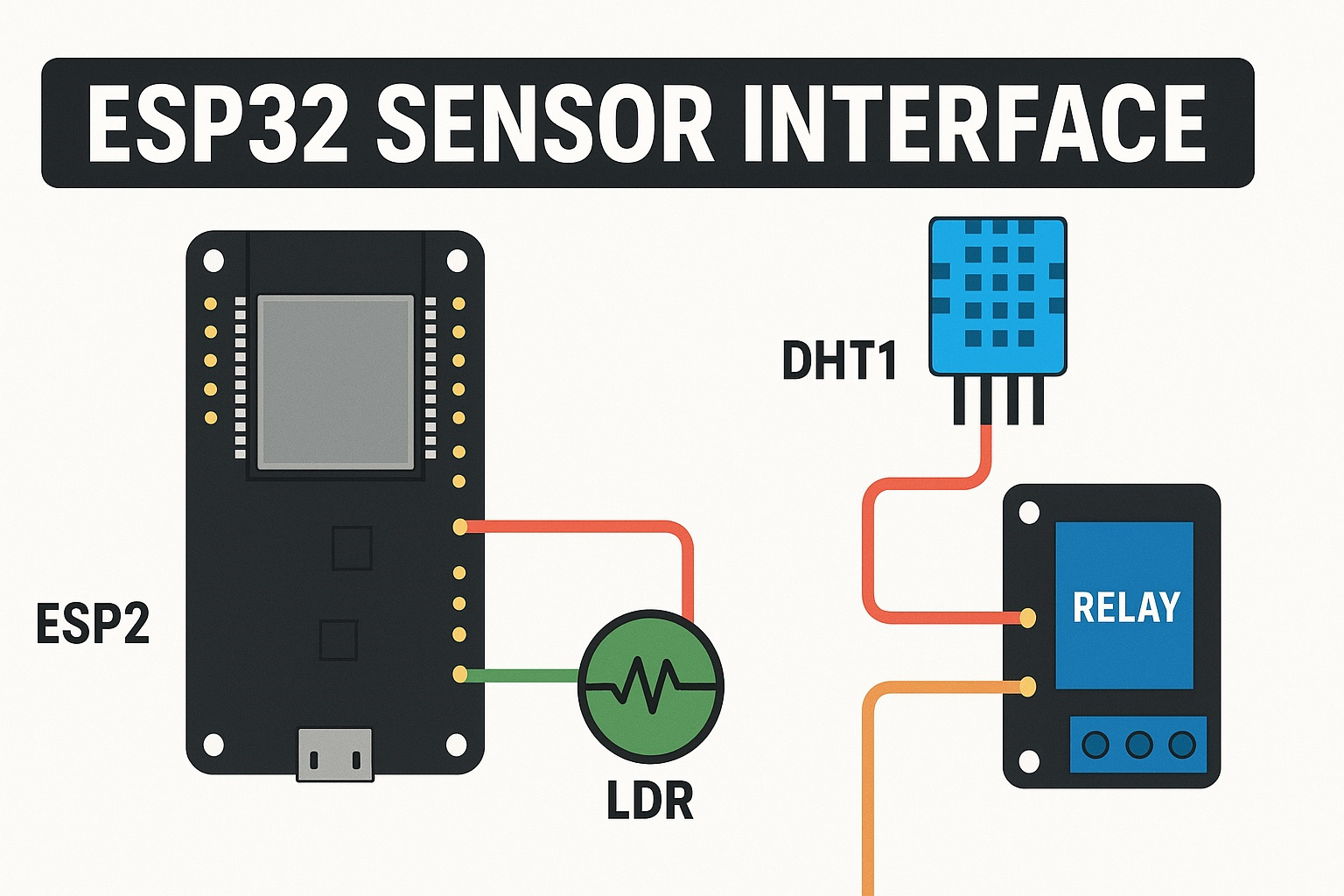

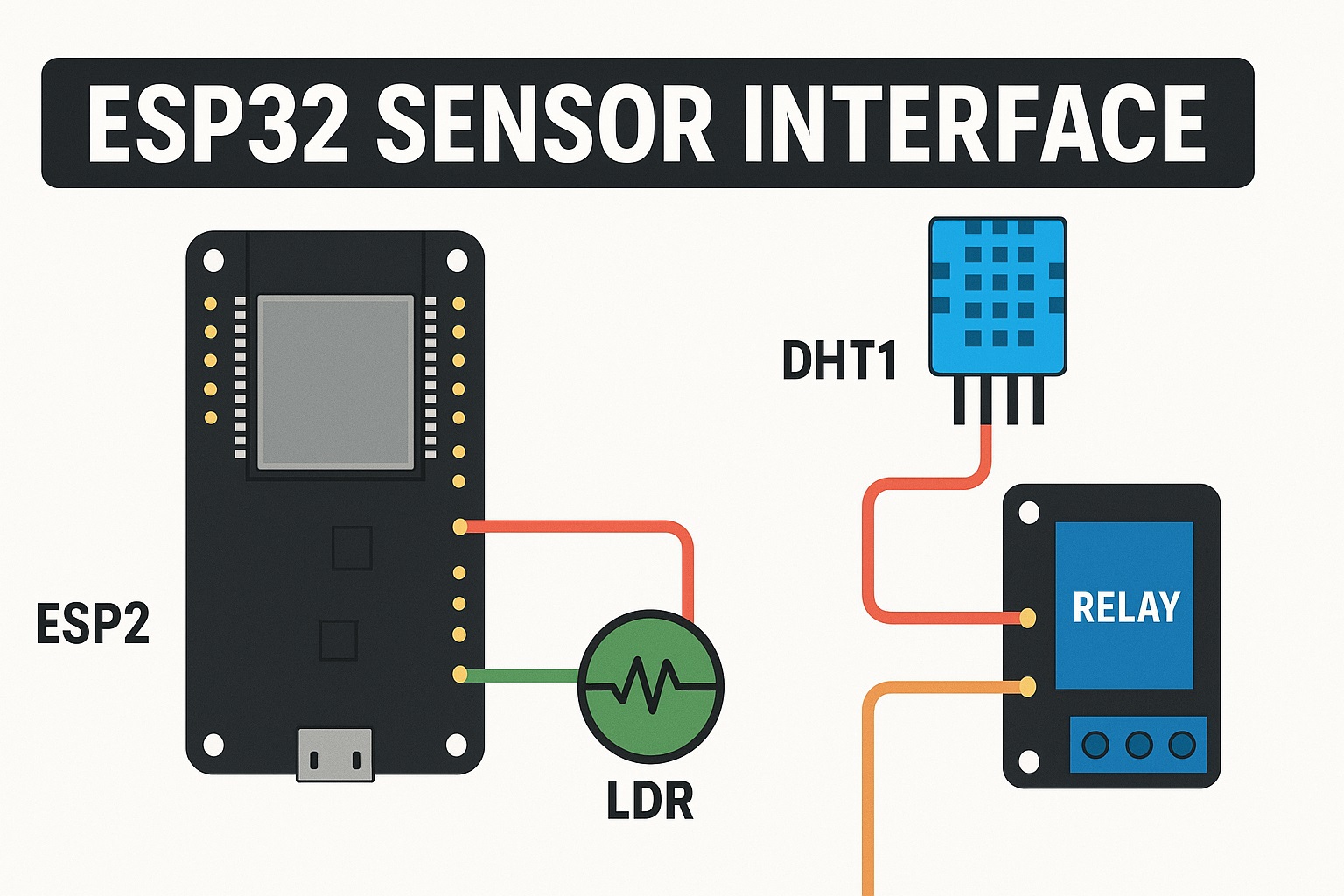

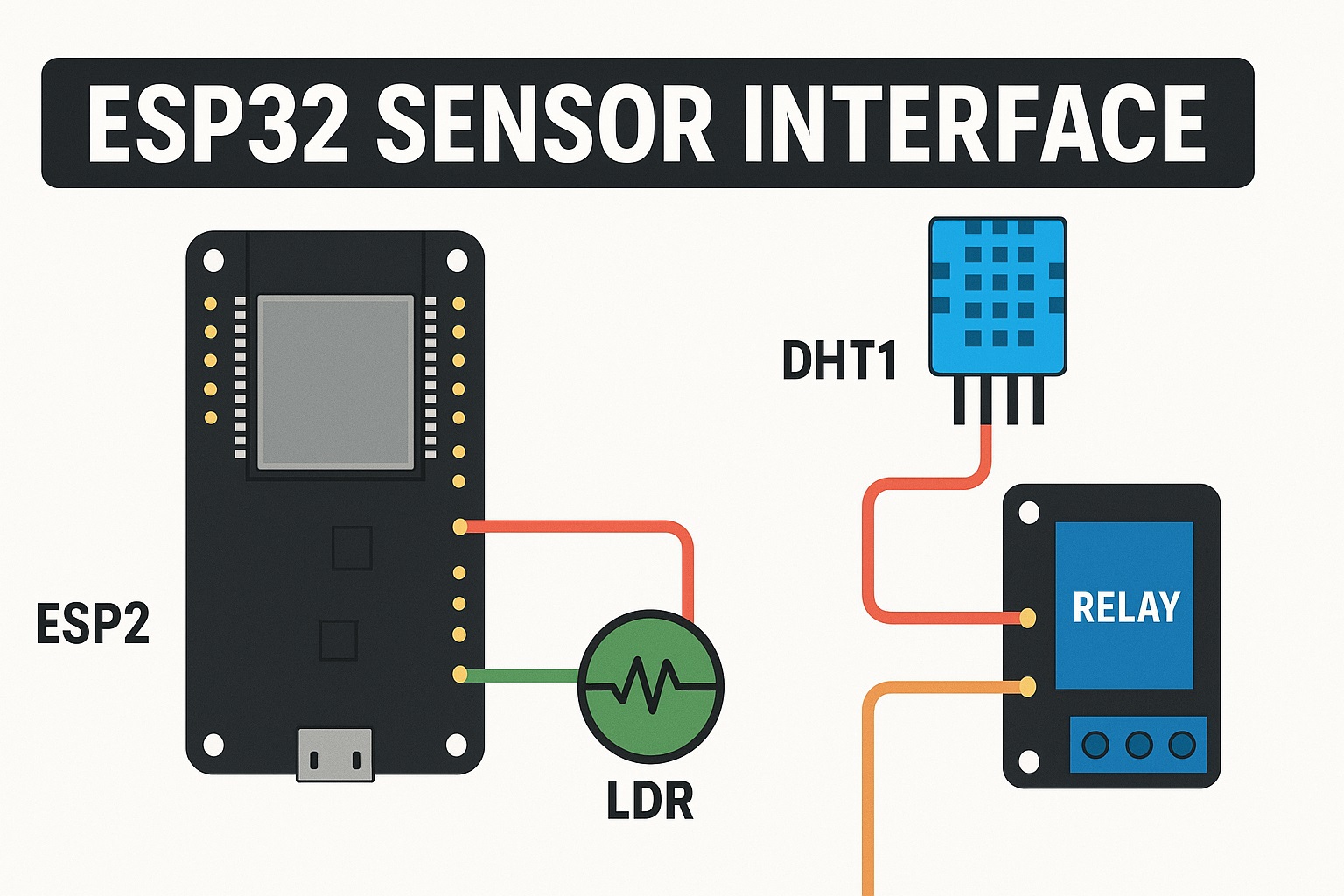

accountantAgra Leather Factory IoT data

In modern leather processing, maintaining precise environmental conditions during the boiler‐tank stage is critical to achieving consistent, high‐quality hides. Too low a temperature (below 55 °C) slows the tanning reaction and prolongs drying times, while temperatures above 68 °C risk scorching or over‐baking the leather. At the same time, excessive ambient humidity (over 80 %) fosters mold growth, corrosion of equipment, and unhealthy working conditions.

2025-05-12